Gelatin capsules are widely used in pharmaceutical and nutraceutical industries for enclosing active ingredients. Their size plays a crucial role in ensuring proper dosage and manufacturing efficiency.

Standardized sizing ensures consistency, while materials like gelatin and additives like titanium oxide enhance functionality. Understanding capsule size is essential for optimal drug delivery and product quality.

Overview of Gelatin Capsules

Gelatin capsules are cylindrical shells made from gelatin, used to enclose active pharmaceutical or nutraceutical ingredients. They are available in hard and soft forms, with varying sizes standardized for consistency. The size of gelatin capsules is critical for ensuring proper dosing and patient ease of use. Hard gelatin capsules are composed of two halves, while soft gelatin capsules are sealed units. The use of gelatin ensures biocompatibility and stability, making them a popular choice in pharmaceutical and dietary supplement industries. Their size and material composition are carefully regulated to meet quality and safety standards.

Importance of Capsule Size in Pharmaceutical Applications

Capsule size is crucial in pharmaceutical applications as it ensures accurate dosing and patient compliance. Proper sizing facilitates consistent drug delivery, preventing underdose or overdose scenarios. Incorrect sizing can lead to formulation inefficiencies, affecting bioavailability and therapeutic outcomes. In manufacturing, precise sizing ensures uniformity in production, minimizing waste and optimizing process efficiency. Additionally, capsule size influences patient ease of swallowing, directly impacting adherence to treatment regimens. Regulatory standards emphasize the importance of size consistency to maintain product quality and safety, making it a critical factor in pharmaceutical development and production processes.

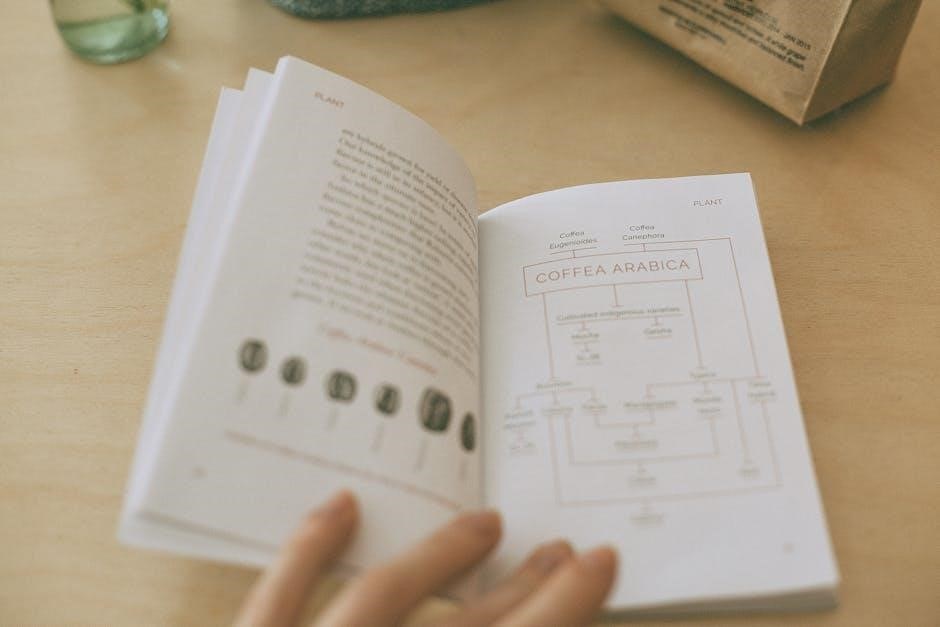

Gelatin Capsule Size Numbering System

The gelatin capsule size numbering system is standardized, based on capsule diameter and capacity. Numbers increase as size decreases, ensuring consistency and proper filling material selection.

Understanding the Standard Size Designations

Standard size designations for gelatin capsules are based on their internal diameter and length, determining the volume of material they can hold. The sizing is standardized worldwide, with specific numbers assigned to each size. Smaller numbers correspond to larger capsules, while higher numbers indicate smaller sizes. This system ensures consistency in manufacturing and filling processes. The designations are critical for maintaining uniformity in drug delivery and dosage accuracy. Understanding these standards is essential for selecting the appropriate capsule size for specific applications, ensuring optimal performance and product quality.

How Capsule Sizes Are Measured and Categorized

Gelatin capsule sizes are measured using precise tools like calipers or gauges to determine their length and internal diameter. These measurements are categorized into standard size designations, ensuring consistency across manufacturing processes. The sizing system ranges from smaller numbers (larger capsules) to higher numbers (smaller capsules), with each size accommodating specific volumes of material. This method ensures uniformity in production and application.

The categorization also considers the capsule’s material properties, such as gelatin type and additive content, which influence size stability and functionality. This systematic approach guarantees reliable performance and dosing accuracy in pharmaceutical and nutraceutical applications.

Manufacturing Standards for Gelatin Capsules

Gelatin capsules are manufactured under strict GMP guidelines, ensuring high-quality materials and precise size consistency. Regulatory compliance and rigorous testing guarantee reliable performance and safety in pharmaceutical applications.

Industry Regulations and Quality Control

Gelatin capsules must adhere to strict regulatory standards set by global authorities like the FDA and EMA. Quality control measures ensure capsules meet size, strength, and purity requirements. Rigorous testing, including dissolution and disintegration tests, guarantees consistent performance. Manufacturing facilities comply with GMP guidelines, ensuring a sterile and controlled environment. Regulatory reports highlight market trends and safety standards, driving innovation in capsule production. Compliance with these standards is crucial for maintaining product integrity and consumer trust in pharmaceutical and nutraceutical applications.

Role of Gelatin in Determining Capsule Size

Gelatin’s properties significantly influence capsule size and integrity. Its bloom strength and viscosity affect capsule wall thickness and durability. High-quality gelatin ensures consistent capsule sizing, critical for accurate dosing. The addition of titanium oxide enhances opacity and stability. Particle size control in gelatin ensures uniform capsule formation. These factors collectively determine the final capsule dimensions, making gelatin a pivotal component in achieving precise and reliable capsule sizes for pharmaceutical and nutraceutical applications.

Common Gelatin Capsule Sizes

Gelatin capsules are available in standard sizes, including 00, 0, 1, 2, 3, and 4 for hard capsules, and softgel sizes like 10, 20, and others, catering to various applications.

Size Ranges for Hard Gelatin Capsules

Hard gelatin capsules are available in standardized sizes, typically ranging from 000 (triple zero) to size 4. These sizes are designated based on their internal volume and length. The 000 size is the largest, accommodating bulkier powders, while smaller sizes like 4 are used for denser or more potent substances. Standardization ensures consistency in manufacturing and dosing. The size guide helps manufacturers select appropriate capsules for specific active ingredients, ensuring proper fit and functionality; Regulatory bodies maintain strict guidelines to ensure uniformity across production lines globally.

Size Ranges for Soft Gelatin Capsules

Soft gelatin capsules, also known as softgels, are available in various sizes, typically ranging from size 10 to size 20. These sizes correspond to the diameter of the capsule in millimeters. Size 10 softgels are smaller, often used for liquids or semi-solid formulations, while size 20 softgels are larger, accommodating more viscous or voluminous contents. The flexibility of soft gelatin allows for precise sealing, preventing leakage and ensuring the integrity of the encapsulated material.

The size selection depends on the viscosity and volume of the filling material, ensuring optimal encapsulation and delivery of active ingredients. This adaptability makes soft gelatin capsules highly popular in both nutraceutical and pharmaceutical applications, enhancing bioavailability and patient convenience.

Gelatin capsules come in standardized sizes, ranging from 000 to 5, with each size indicating specific dimensions. This guide helps in selecting the right size for different applications.

Capsule Size Chart for Different Applications

A gelatin capsule size chart categorizes capsules by numerical sizes, ranging from 000 (largest) to 5 (smallest). Each size corresponds to specific dimensions and capacities, ensuring precise dosing. For pharmaceuticals, larger capsules like 00 or 0 are often used for powders or bulky ingredients, while smaller sizes (1-4) are ideal for liquids or smaller doses. In nutraceuticals, size selection depends on the active ingredient’s volume and patient preferences. This standardized sizing ensures consistency and ease of use across various applications, from medications to dietary supplements.

Matching Capsule Sizes to Active Ingredients

Selecting the appropriate gelatin capsule size for active ingredients ensures optimal dosing and patient compliance. Capsule sizes are chosen based on the particle size and viscosity of the filling material, as well as the required fill weight. Larger capsules are suitable for bulky powders, while smaller sizes are ideal for liquids or fine powders. The size must also balance the active ingredient’s volume with the need to minimize excipients. This patient-centric approach ensures ease of swallowing and consistent drug delivery, enhancing therapeutic efficiency and patient compliance.

Factors Influencing Capsule Size Selection

The size of gelatin capsules is influenced by the particle size and viscosity of the filling material, as well as the desired dosage accuracy and manufacturing efficiency.

Particle Size of the Filling Material

The particle size of the filling material significantly impacts the selection of gelatin capsule size. Finer particles require smaller capsules to ensure proper filling and avoid overflow.

Larger particles may necessitate bigger capsules to accommodate the volume. The distribution of particle sizes also affects flow properties, influencing how material fills the capsule evenly.

Measuring particle size ensures optimal capsule fit, preventing issues like clogging or inconsistent dosing. This step is crucial for maintaining manufacturing efficiency and product quality.

Viscosity and Flow Properties of the Content

The viscosity and flow properties of the filling material play a critical role in determining the appropriate gelatin capsule size. Materials with higher viscosity require larger capsules to ensure smooth filling and uniformity.

Thinner, more fluid materials can be filled into smaller capsules without compromising efficiency. The flow properties also influence how evenly the content distributes within the capsule.

Understanding these characteristics helps optimize capsule size selection, ensuring reliable manufacturing processes and consistent product quality.

Applications of Gelatin Capsules

Gelatin capsules are widely used in pharmaceuticals, nutraceuticals, and dietary supplements. They are popular for encapsulating powders, liquids, and semi-solids due to their tasteless, odorless, and versatile nature.

Pharmaceutical Applications

Gelatin capsules are widely used in the pharmaceutical industry for drug delivery due to their versatility and biocompatibility; They are commonly used to encapsulate active pharmaceutical ingredients (APIs) in both hard and soft gelatin forms. Hard gelatin capsules are ideal for powders or granules, while soft gelatin capsules are preferred for liquids or semi-solids. The inert nature of gelatin ensures minimal interaction with the drug, preserving its efficacy. Capsule sizes are standardized to accommodate varying doses, making them suitable for different patient needs and drug formulations. Their consistent release properties ensure reliable therapeutic outcomes.

Nutraceutical and Dietary Supplement Applications

Gelatin capsules are extensively used in the nutraceutical and dietary supplement industry due to their ability to encapsulate a wide range of ingredients, including vitamins, minerals, and herbal extracts. Their inert properties ensure the stability and bioavailability of sensitive compounds. Soft gelatin capsules are particularly popular for oils and liquid-based supplements, offering enhanced absorption. The variety of capsule sizes allows for tailored dosing, catering to diverse consumer needs. This versatility makes gelatin capsules a preferred choice for delivering high-quality nutritional products, ensuring consumer satisfaction and efficacy.

Measuring and Testing Gelatin Capsules

Gelatin capsules are measured using precise tools like calipers and gauges to ensure dimensional accuracy. Testing involves assessing physical durability, such as burst strength, to maintain content integrity. Quality assurance processes, including random sampling, are implemented to ensure consistency and reliability across production batches.

Tools and Techniques for Size Measurement

The measurement of gelatin capsules typically involves using precision tools like digital calipers or specific gauges to assess length and diameter. Optical measuring devices, such as vision systems, are also employed for high accuracy. Additionally, capsule sorters and sizing templates help categorize capsules into standardized sizes. These tools ensure consistency and compliance with industry standards. Regular calibration of equipment is essential to maintain reliability in size determination, ensuring that each capsule meets specified tolerances for pharmaceutical or nutraceutical applications.

Quality Assurance in Capsule Manufacturing

Quality assurance in gelatin capsule manufacturing ensures consistency, reliability, and compliance with industry standards. This involves rigorous testing of raw materials, in-process controls, and finished product inspections. Key aspects include verifying capsule dimensions, hardness, and moisture content. Advanced techniques like visual inspection systems and mechanical strength testing are used to identify defects. Documentation and traceability are maintained to ensure accountability. These practices guarantee that capsules meet regulatory and customer expectations, ensuring safe and effective drug delivery.

Shelf Life and Storage Considerations

Gelatin capsules require controlled storage conditions to maintain stability. Moisture, temperature, and light exposure must be managed to prevent degradation. Proper storage ensures optimal shelf life.

Impact of Storage Conditions on Capsule Integrity

Storage conditions significantly influence the integrity of gelatin capsules. High humidity can cause capsules to absorb moisture, leading to softening or stickiness, while low humidity may result in brittleness. Temperature fluctuations can cause gelatin to melt or become misshapen, affecting capsule structure. Light exposure, particularly for photosensitive contents, can indirectly impact integrity by degrading active ingredients. Maintaining controlled environments with optimal humidity, consistent temperatures, and limited light exposure is crucial to preserve capsule size, shape, and functionality.

Best Practices for Maintaining Capsule Quality

To ensure gelatin capsule quality, implement rigorous quality control measures, including regular inspections and testing. Store capsules in airtight containers to prevent moisture absorption and contamination. Maintain consistent humidity and temperature levels during storage to preserve capsule integrity. Train personnel in proper handling techniques to avoid damage. Use high-quality gelatin and ensure compliance with manufacturing standards. Regularly calibrate equipment to maintain precise capsule size and shape. These practices help uphold the structural and functional integrity of gelatin capsules throughout their shelf life.

Regulatory Considerations

Regulatory compliance ensures gelatin capsules meet safety and quality standards. Adherence to international regulations guarantees consistency and consumer trust, guiding proper manufacturing and distribution practices.

Compliance with FDA and Other Regulatory Bodies

Gelatin capsules must comply with FDA and international regulatory standards to ensure safety and quality. The FDA regulates capsule manufacturing under cGMP guidelines, ensuring adherence to strict quality control measures. Capsules are tested for dissolution, disintegration, and physical dimensions to meet USP (United States Pharmacopeia) standards. Regulatory bodies like EMA (European Medicines Agency) and TGA (Therapeutic Goods Administration) enforce similar stringent requirements. Compliance ensures consistency, safety, and efficacy, maintaining trust in gelatin capsules for pharmaceutical and nutraceutical use globally.

Labeling and Packaging Requirements

Proper labeling and packaging of gelatin capsules are critical for compliance and consumer safety. Labels must include product name, capsule size, batch number, and expiration date. Packaging materials must protect capsules from moisture, light, and contamination. Regulatory bodies require child-resistant packaging for certain products. Storage instructions and handling precautions should be clearly stated. Compliance with ISO and GMP standards ensures packaging integrity and safety. Accurate labeling and secure packaging are essential for maintaining product quality and meeting regulatory expectations in pharmaceutical and nutraceutical industries.

Future Trends in Gelatin Capsule Development

Future trends in gelatin capsule development focus on sustainability and innovation. There is a growing interest in plant-based alternatives to traditional gelatin, catering to vegan and vegetarian preferences. Advances in 3D printing technology may enable customized capsule sizes and shapes for personalized medicine. Additionally, controlled-release formulations and biodegradable materials are expected to gain prominence. These trends aim to enhance patient convenience, improve drug delivery efficiency, and align with environmental and ethical consumer demands, shaping the future of gelatin capsules in pharmaceutical and nutraceutical industries.